Forensics related to metal wall installations is used to explain what determines visual acceptance.

Panel Fabrication Tolerance

- Length

- Squareness

- Viewed from front

- Measured across sheet

- View from panel side

- Measured across sheet

Panel Installation Tolerance

- Panels to be installed:

- True to line and level/plumb

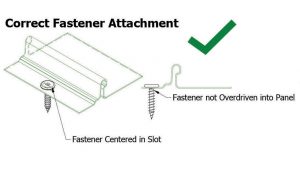

- Exposed fasteners shall be installed in a straight line

- Field Measurements

- Panel shall be measure with panels positioned without restraint and with enough support to prevent significant distortion or deflection

- Substrate must be straight and true

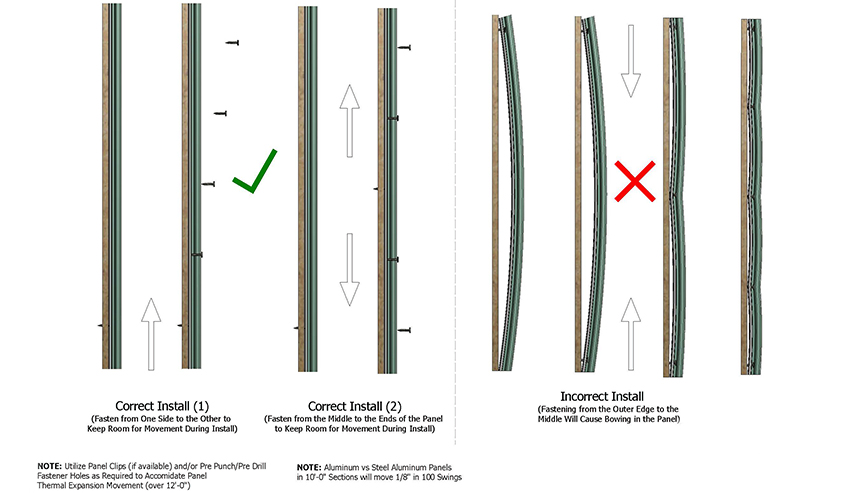

- Panels should be progressively installed so that overall misalignment or tolerance issues are not focused in a single panel on a wall

Panel Finish

- Surface imperfection

- Dents, dimples, and defects from manufacturing (coil breaks, fluting, camber)

- Paint finish and color tolerances and performance values

Panel Deflection

- Can be caused by environmental factors (wind)

- Sub-structure tolerances and movement

- Allowable deflection by code L/60

- (IBC Table 1604.3)

Panel Face Distortion – Perceived Oil Canning

- Can be caused by all previous identified factors

- Percieved oil canning is not considered a cause for rejection (see MCA document)

- Effects of thermal movement

- Clips, slotted holes, panel breaks

- Types of material (steel, aluminum, natural metals

- All have differrent expantion and contraction values

- Steel 1/16″ in 10′-0″/100° of temperature change

- Aluminum 1/8″ in 10′-0″/100° of temperature change

- All have differrent expantion and contraction values