Gaten Series | Functional Systems

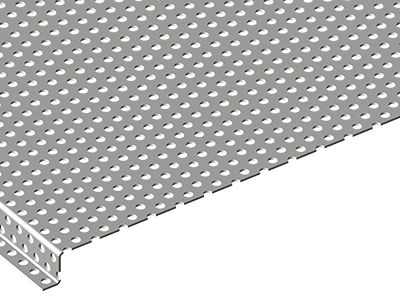

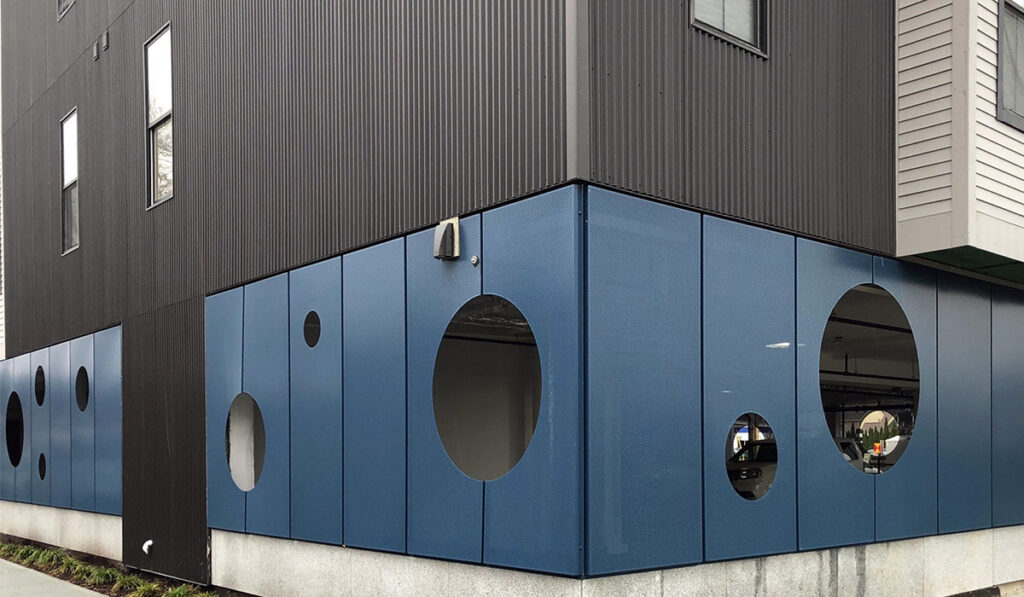

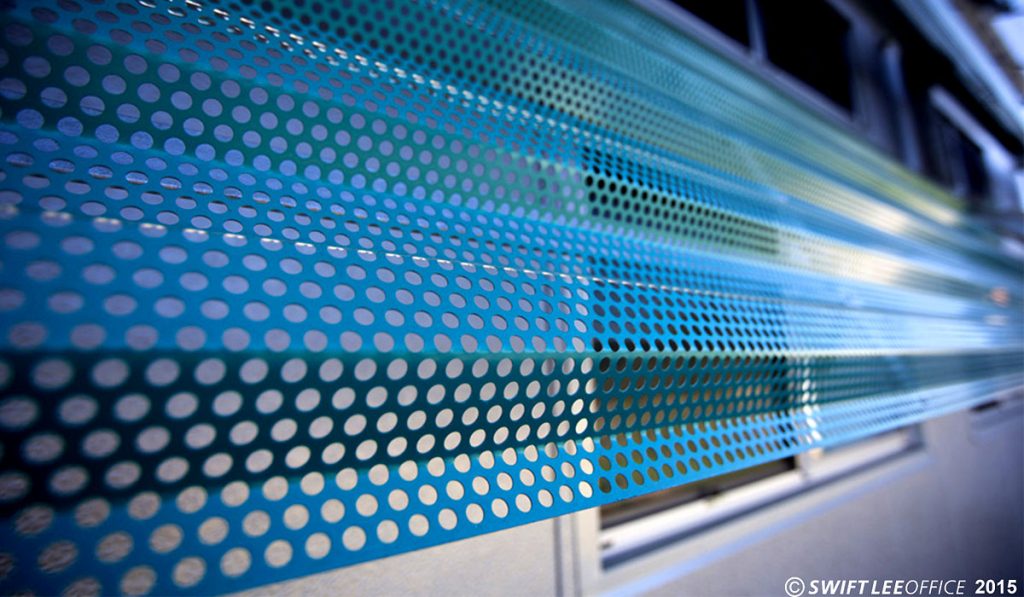

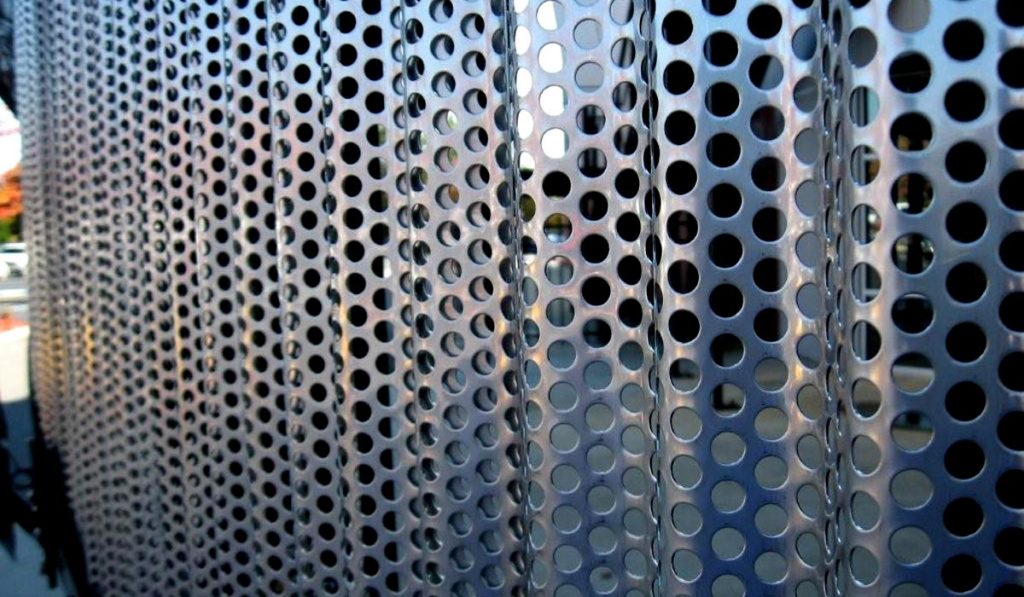

Perforated metal panels are ideal for use as ventilation, acoustical panels, passive sun shading, sunscreens, covers, enclosures, dividers, and more. They can also be used to control the passage of air, light, and sound.

ATAS offers numerous hole size and placement combinations for perforated metal panels. While standard rounds holes are the most economical, custom shapes and variations are available at an additional cost and with design limitations.

An aluminum substrate is recommended for all exterior perforated applications due to its inherent corrosion-resistant properties.

Six standard patterns available:

- A13: ⅛” holes, 3⁄16″ staggered centers, 40% open area

- A15: ⅛” holes, ¼” staggered centers, 23% open area

- A23: 1⁄4″ holes, ½” staggered centers, 23% open area

- A24: 3⁄8″ holes, ½” staggered centers, 51% open area

- A19: 3⁄16″ holes, 5⁄16″ staggered centers, 33% open area

- A25: 3⁄8″ holes, 9⁄16″ staggered centers, 40% open area

A perforation pattern is specified as follows:

Hole Size x Center to Center Distance x Orientation and the Open Area Produced

Example: ATAS Standard Pattern “A23” is: .25” x .5” OC Staggered, 23% OA

Translation: The holes are ¼” in diameter, spaced ½” apart center-center diagonally at a 60 degree angle, which produces 23% open area, or metal loss – 23% of the me

- Gaten Series Perforated Metal Panels Product Brochure

- A13 Standard Hole Pattern

- A15 Standard Hole Pattern

- A19 Standard Hole Pattern

- A23 Standard Hole Pattern

- A24 Standard Hole Pattern

- A25 Standard Hole Pattern

- ATAS Color Chart

- Finish Warranty

- LEED v4

- ATAS Aluminum Recycled Contents

- ATAS Steel Recycled Contents

- Solar Reflectance & Thermal Emittance Chart

- ATAS Manufacturer Qualification Statement