Rigid Wall II offers a sleek appearance and design solutions for any number of project objectives.

Splice Plate

- Behind panel

- ⅛” to ¼” gap

- Appropriate sealant

- Neoprene behind splice plate

- Pop rivets or VHB tape – one side of panel

Note: Same detail used with elite miters

Splice Plate – Open Framing

- Added framing needed for the splice plate

- Add neoprene behind the splice plate to keep the face of panel on the same plane

- Appropriate tube butyl sealant

- Pop rivet or VHB tape, one side of panel

Recommended: Lapping panels randomly throughout elevations to minimize continuous sight lines

Factory Pre-notching – Open Framing

- 1” pre-notch on both ends of panel

- Appropriate tube butyl sealant

- No pop rivet

- Neoprene behind splice plate

- ⅛” to ¼” gap for thermal expansion

- Requires extra framing

- Not to be done with .050 aluminum

Note: Contractor must add on the 2” to panel length when doing material cut list

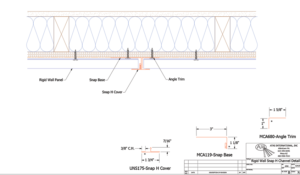

Alternative Option

- Full length panels

- Contractor cuts panels in field

- Eliminates the panel end flare

- Snap H trim or extrusions

- Avoids using a splice plate or overlap