Purpose of Backside Coating

- Finish side protection

- Backside coating must be compatible with top side coating

- Protection during coiling stages when exiting the paint line

- Protection during

- Recoiling

- Slitting process

- Sheet stock storage

- Lubrication

- Paint finish on top side and backside acts as lubrication

- Offers protection to

- Slitter

- Roll former

- Gives traction to push or pull material through rollers

- Tooling

- Easier handling and sliding of material

- Corrosion resistance to base metal

- Dissimilar metal protection

- Backside coating acts as a barrier between the panel and the framing

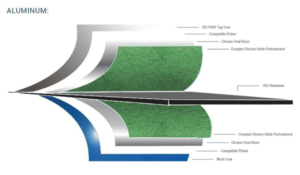

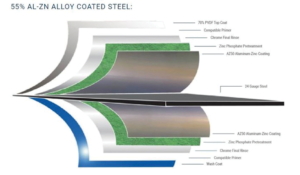

What is backside coating?

- Primer with a back coat

- Off-white/light gray

- Notify custom if project has backside coating exposed there maybe a color variance to top side coating

Backside Coatings on other substrates

- Plastisol on zinc

- Epoxy on metal composite materials (MCM) & insulated metal panels (IMP)

- 70% PVDF

- May be offered on both sides due to

- Visibility of backside coating

- Exposed to outside environment

- If project requires warranty on both sides

- May be offered on both sides due to